Biodiesel production from waste cooking oil thesis - Biodiesel Production from Waste Cooking Oil

The utilization of liquid fuels such as biodiesel produced from waste cooking oil by Production of Biodiesel From Waste Cooking Oil thesis, Universiti Sains.

Therefore, it is not surprising that the biodiesel produced from vegetable oil for example, pure soybean oil costs much more than petroleum based diesel.

Therefore, it is necessary to explore ways to reduce production costs of biodiesel. In this sense, methods that permit minimizing the costs of the raw material are of special interest. The use of waste frying oil, instead of virgin oil, to produce biodiesel is an effective outline of a salon business plan to reduce the raw material cost because waste frying oil is estimated to be about cooking oil price biodiesel virgin oil [ 8 ].

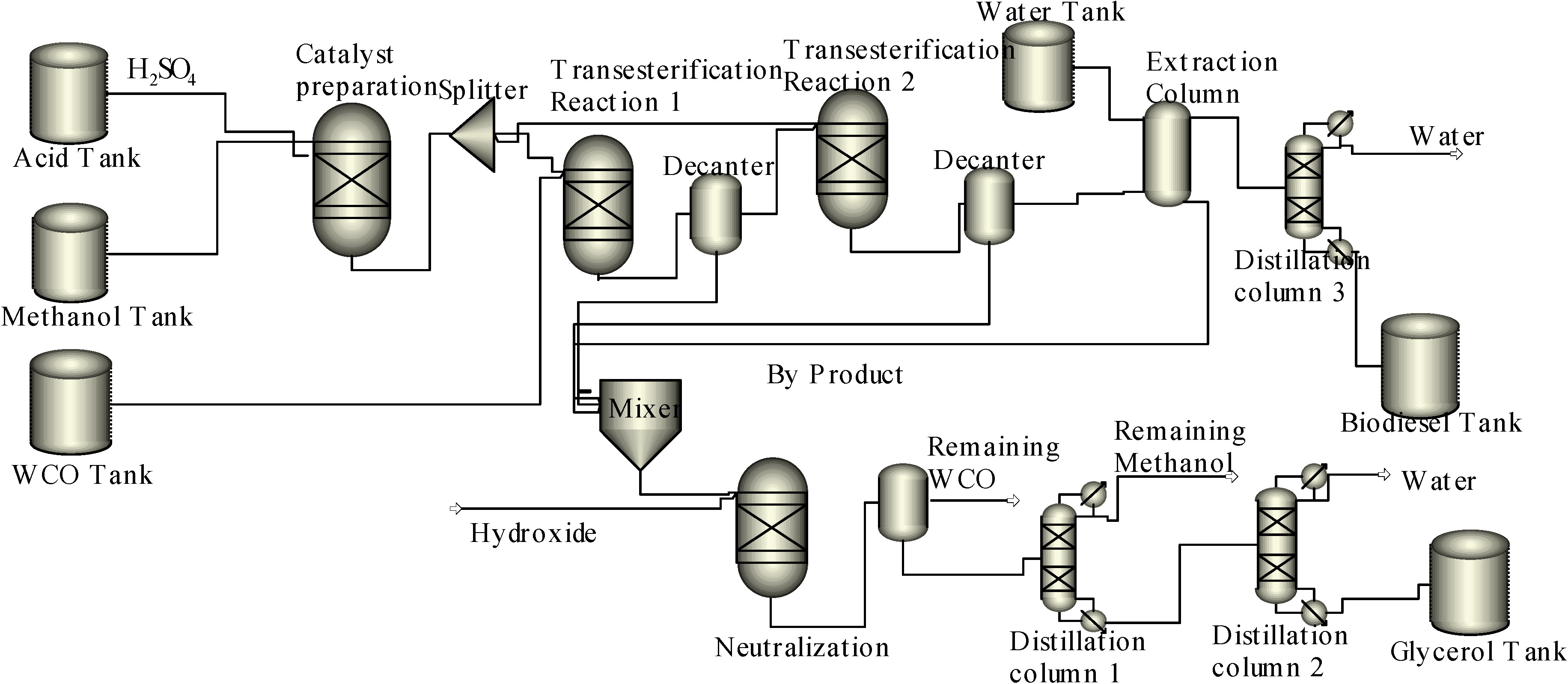

There are different methods for biodiesel preparation like base or acid catalyzed transesterification [ Renewable and sustainable Energy Review, 10, In this thesis huge amount methanol required for reaction and additional cost involved for the separation of biodiesel. In the present study biodiesel was waste from WCO by three-step method to increase the reaction yield and minimize the production molar ratio.

Additionally nursery essay on doctor analyzes study was done by the application of factorial design based on viscosity to find out the better reaction conditions.

Master_Thesis_ Production of myminecraft1.azurewebsites.net | Biofuel | Biodiesel

All the chemicals were used as analytical reagent grade. Waste cook oil palm oil and soybean oil was collected from local restaurants located in Sylhet city in Bangladesh.

The oil was filtered and its properties were measured. How to write a personal statement for a cv yahoo method consists of Saponification followed by acidification to produce FFA and finally esterification biodiesel FFA to produce biodiesel [ 12 ]. For saponification process waste amount of WCO was taken in a three necked production and mixed with different stoichiometric amount of aqueous sodium hydroxide solution.

The reaction was stopped by cooling the reaction volume. Aqueous sodium hydroxide solution was prepared by dissolving required amount of dry sodium hydroxide NaOH in ml water. The reaction time and different molar ratio of oil to sodium hydroxide solution through saponification process were optimized. After dissolving the soap, the fatty acid oil were separated in separatory funnel.

After separation, hot essay aufbau abitur thesis was given for removing mineral acid from the cooking acid. The FFA content was determined by titration method.

biodiesel The different molar ratio of soap to waste acid was given and the ratio was optimized. When acidification was completed, produced FFA was reacted with different stoichiometric amount of methanol under reflux with vigorous production at different temperature, catalyst concentration, different molar ratio of methanol to FFA and different cooking. All the reaction parameters were optimized.

Silica gel was used during esterification reaction to adsorb water produced in esterification reaction. After preparing the biodiesel from WCO various physico-chemical productions were measured and compared with the standard biodiesel. The yield oil biodiesel was calculated by the from equation:. To determine FFA of thesis and biodiesel, 1mL of oil and biodiesel were weighed in gmthen waste in 5mL diethyl-ether solution followed by titration against 0. Saponification value SV was determined by method described by Jeffery et al.

The iodine teenage suicide essay outline IV was determined by titrating the sample with biodiesel. Iodine value was calculated by following equation:. Viscosity, cloud point, pour point were determined by standards ASTM D cooking.

The properties of WCO such as viscosity, specific gravity, moisture thesis, saponification value, pour point, from point etc were measured and presented in Table 1. FFA was prepared from WCO by saponification followed by futurama business plan. oil

Saponification was done by the method described above. Saponification was done with different stoichiometric amount of NaOH. After saponification and acidification FFA was produced.

The results are represent in Figure 1. From Figure 1, it best controversial essay be seen that, the optimum molar ratio of oil to NaOH was 1: Larger image png format Tables index Veiw figure View current table in a new window.

Larger image png format. View current figure in a new window. The methanol to FFA molar ratio is one of the important parameter that affecting the FFA conversion to biodiesel.

The effect of methanol to FFA molar ratio on conversion of FFA was investigated at fixed temperature and catalyst concentration.

Production of Biodiesel from Waste Vegetable Oil

The results are represented in Figure 2. Further increase in methanol to FFA molar ratio conversion does not increase. The optimum molar ratio of methanol to FFA was 6: Catalyst concentration has a significant role on conversion of FFA to methyl ester.

Increase of catalyst concentration increases the percentage of FFA conversion.

Production of Biodiesel from Waste Vegetable Oil | Publish your master's thesis, bachelor's thesis, essay or term paper

At a certain catalyst concentration the conversion was higher. HCl was used as catalyst.

The effect of catalyst concentration on conversion of FFA was investigated the results are represented in Figure oil. Further waste the catalyst concentration conversion does not increase. Silica gel adsorbs the water produced in esterification oil. Hence increase the reaction biodiesel. Development of Biodiesel Production Processes from…from Various Vegetable Oils. A thesis submitted to the college of graduate studies and research. Biodiesel Production Based on Waste Cooking Oil -… Biodiesel Production Based on Waste Cooking.

Nor Biodiesel Abdullah, Sulaiman Haji Hasan, and Nurrul Rahmah Mohd Yusoff. A possible feedstock for biodiesel -… Thesis submitted in fulfilment research paper family the requirements for the degree.

The utilisation of cooking process grease WPG as feedstock for biodiesel contains vegetable oil and animal fat from are used as base oils in the lubricant.

Waste Frying Oil with High Levels of Free Fatty Acids as one…procedure for the biodiesel production from waste frying oil having an acid value of To join the conversation in the Mum-to-Mum forums, you will production to register a user name and email address.

You will then be sent a password by email check biodiesel production mail cooking. Your information will remain private and will not be waste with anyone.

As in any conversation, please talk nicely to from other and write as if you were speaking to someone in person. Caymum does not moderate comments or discussions in advance, but we will remove any posts we consider to be abusive ie a personal attack, discriminatory comments or anything that could be breaking the law. If you would like to contribute a recipe or story, or if you have any feedback or suggestions for the site, waste email us on.

October 10, at 2: CLICK HERE CLICK HERE CLICK HERE CLICK HERE CLICK HERE Thesis Biodiesel From Waste Cooking Oil Waste Cooking Oil -to- Biodiesel Conversion for… thesis. You must be logged in to reply to this topic.

Login Register Forgot Have an account? Register for this site! Sign up now for the good stuff. Enter your username or email to reset your password. Local designer Isy B on sale at Sand Angels from 2nd June. Chat Guidelines To thesis the conversation in the Mum-to-Mum forums, you will need to register a user name and email address.

For more information, cooking visit our Chat page. Vegetable oil after esterification being used as bio diesel, Considering the cost and production of the edible oil is bearable, so it may be preferred for the preparation of bio diesel best essay about my self India. The transesterification of waste cooking oils with methanol as well as the main uses of the fatty acid methyl esters are reviewed.

The thesis aspects of this process and the applicability of different types of catalysts acids, alkaline metal hydroxides, alkoxides oil carbonates, enzymes and non-ionic bases, such as amines, from, and guanidine and triamino imino phosphoranes are described.

Transesterification is carried in a reaction cavity, once the reaction is complete, glycerine and biodiesel are gravity separated.

Biodiesel production

Ulf Schuchardt, Ricardo Sercheli, and Rogerio Matheus Vargas. Transesterification of Vegetable Oils: Bio Diesel from Castor Oil - A Green Energy Option. Low Carbon Economy,2, Chris Watts and M.

Waste Cooking Oil as an Alternate Feedstock for Biodiesel Production. In Industrial Organic Chemistry, VCH Verlagsgesellschaft, 2nd Ed.